Poured-In-Place Rubber Services by USA Safety Surfacing Experts

Contact Us

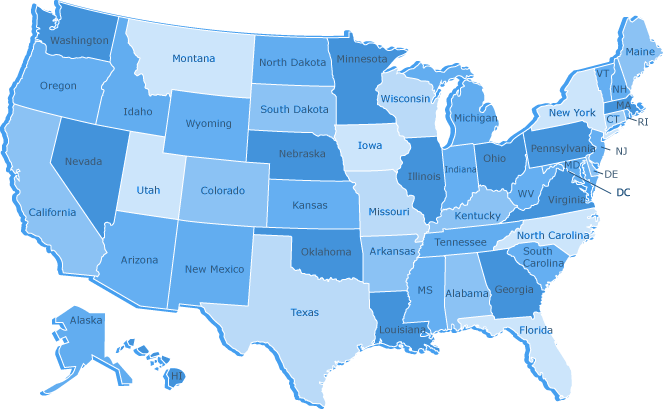

An increasing number of schools, playgrounds, and parks with play areas are investing in our poured-in-place rubber surfacing or PIP Rubber. This product has various advantages, including aesthetics, protection, and ease of maintenance. Do you want to learn more about PIP rubber surfacing in your state? If your neighborhood requires a healthy and appealing playground surface, Poured-In-Place Rubber provides the best quality and trusted rubber surfacing solutions.

USA Safety Surfacing Experts sells and installs a variety of products in your state and around the US. Poured-in-place is a substance that is both durable and long-lasting. The surface is also smooth, dependable, and durable. Children are less likely to sustain severe injuries when falling on these surfaces. We are a one-stop shop with everything you need to build a long-lasting playground area.

Safety Surfaces Done By Professionals

We have been providing high-quality products since our establishment, and our portfolio presently includes the construction of more than two million square feet of safety surfaces and leisure areas. We have completed projects ranging from the most simple to those of sophisticated graphic designs. Anything from delivering a quotation to completing the process is handled efficiently by us. We not only offer professional installation, but we also offer our expertise to test your playground surfaces and ensure that they follow the requisite protection and quality requirements. If your surfaces need care and maintenance, we will have a trained team to meet your needs. Indoor and outdoor play areas are also featured in our list of completed programs.

We have a long list of satisfied customers all over the states. Municipal engineers, landscape architects, and Parks and Recreation Departments were among them. PIP rubber has also been installed in school districts, churches, the military, and a variety of other organizations. USA Safety Surfacing Experts provide expert planning, building, and installation services for rubber playground surfacing. There is no task too large or too small for us to tackle. One of our customer service agents would gladly go over your project with you. To learn more, give us a call today for a free, no-obligation quote!Y

ou Get To Choose How You Want Your Surface Made

A two-layer system is used for poured-in-place rubber surfacing. The base layer is a Styrene-Butadiene Rubber (SBR) foundation which serves as the surface’s effect absorption layer. The Styrene Butadiene Rubber Base is made entirely of recycled materials that would otherwise end up in a landfill. The crown layer is colored coated made of synthetic rubber granules called Ethylene Propylene Diene Monomer (EPDM). Our qualified in-house installation team custom mixes and mixes the Poured-In-Place Rubber surfacing on-site to produce a smooth safety board. In terms of styles, patterns, emblems, and colors for the sandbox, anything can be possible to make with us, the only limitation is your creativity. Including logos and classic games such as Four Square, HopScotch and Tic Tac Toe adds value and aesthetic appeal to your custom surface.

Every rubber surface provided by our company complies with the uniform specification for determining the availability of surface structures around and under playground equipment. Our poured-in-place rubber surfacing follows and exceeds the minimum specification for collision attenuation of surfacing products within playground equipment usage zones. Please email us if you would like a copy of our third-party surface monitoring.

The Advantages of Poured-In-Place Surfacing.

Seamless slip-resistant surface, drains water fast, simple to maintain and clean, and is extremely long-lasting. We can make sure your surface installation complies with The Americans with Disabilities Act (ADA) for easy wheelchair access. This can be built both indoors and outdoors; assuring consistent shock absorbency, using materials that do not move out of place during play.

Questions We Answer Daily

The poured-in-place rubber surfacing is a kind of playground flooring that is smooth and made up of very tiny rubber granules that are adhered together. It is not sloppy (like rubber mulch, wood chips, sand, or dirt). The deeper you prefer the rubber surfacing, the more expensive it will be, though, adding more depth to the surface, you add more durability and increasing the overall performance of the playground. The fact is that natural rubber produces latex (a skin sensitizer), our testing revealed no skin discomfort from interaction with poured-in-place rubber surfacing products. While poured-in-place rubber surfacing (commonly called PIP) is the most commonly used and accurate concept in the industry, it is also known as playground flooring, wet pour rubber surfacing, rubberized playground surfacing, or poured rubber flooring. The best well-kept poured-in-place rubber surfaces have a life expectancy of eight years or more. After about 8 years, the surfaces should be tested and resurfaced if necessary. Frequently, only the top layer will reveal wear and tear and will require maintenance. A weekly sweep of debris and organics is required. Commercial cleaners, ideally citric-based, should be used to remove stubborn marks or stains. Plastic-bladed snow shovels are recommended. To avoid icy conditions, ice melt is the ideal product to help keep the surface clear of ice. Most residue and debris can be removed by pressure washing in the spring. Sand is not recommended because it can clog the soil and reduce the porosity of the surface. Since the rubber is porous, water can flow to the sub-base material or drain system. For some water park uses, we may even add a non-porous device. Yes, it can be built on hills, making it ideal for playgrounds with mounds or sloped terrain. Installation is not recommended because it necessitates practice and accurate mixing ratios. The manufacturing expense (rather than labor) is by far the most expensive part of the installation. The cost is entirely dependent on the application, the area surface, the thickness of the rubber, and the colors and patterns. Please email us for the best advice and pricing for your particular project. What Is Playground Poured-In-Place Rubber Surfacing?

How Much Does Poured-In-Place Rubber Cost?

Is Poured-In-Place Rubber Safe?

What Other Terms Are Used For Poured-In-Place Rubber?

How Long Would Poured-In-Place Surfacing Last?

How Do You Clean Poured-In-Place Rubber?

Where Do I Start With Winter Maintenance?

Does Water Drain Into The Rubber?

Will Slopes Be Installed With Poured-In-Place Rubber?

Will We Mount The Rubber On Our Own?

Where Can I Enquire About The Cost?